Discover the power of precision and productivity with Desoutter’s RAPID screw feeding system—an advanced automation solution engineered to streamline your assembly operations. Designed for high-performance environments, RAPID ensures accurate screw delivery, minimizes manual handling, and significantly enhances throughput across a wide range of tightening applications.

Trusted by leaders in the automotive, electronics, and general manufacturing industries, RAPID is the go-to solution where speed, reliability, and precision are non-negotiable. Whether you're optimizing a manual workstation or integrating into a fully automated line, RAPID delivers the performance and flexibility your production demands.

Take a closer look at RAPID in our videos

Desoutter high-Speed, Automated Screw Delivery for Precision Assembly

RAPID's key features

Compatibility

Fully compatible with different kinds of fasteners (screws, nuts, studs...) screwdrivers, controllers and handling systems.

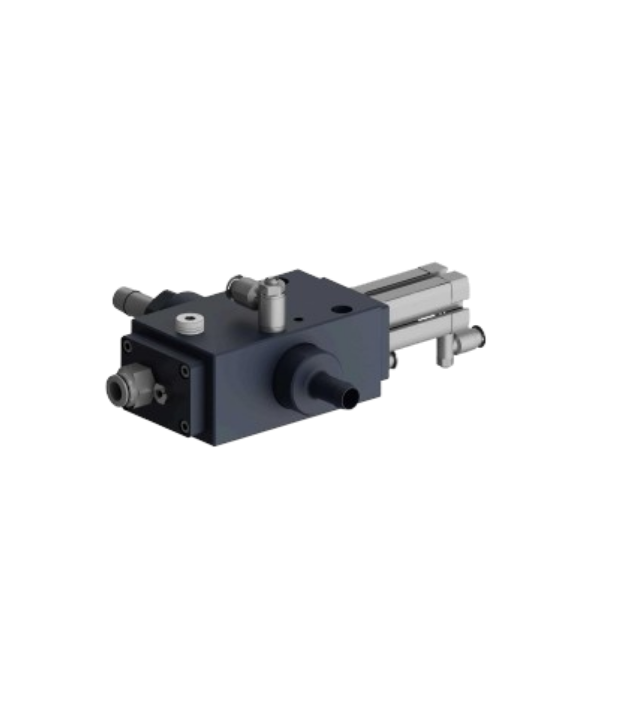

Multiple stroke module options

which fit all tightening directions

Optional functions

Dynamic Reaction Torque / online calibration function

Choice of feeder system

Step feeder or bowl feeder

Multiple types of loading heads

including auto-feeding, vacuum version for hard-to-reach points and pick & place

Optional pneumatic panel & logic control

to simplify integration

Compatibility

Fully compatible with different kinds of fasteners (screws, nuts, studs...) screwdrivers, controllers and handling systems.

Multiple stroke module options

which fit all tightening directions

Optional functions

Dynamic Reaction Torque / online calibration function

Choice of feeder system

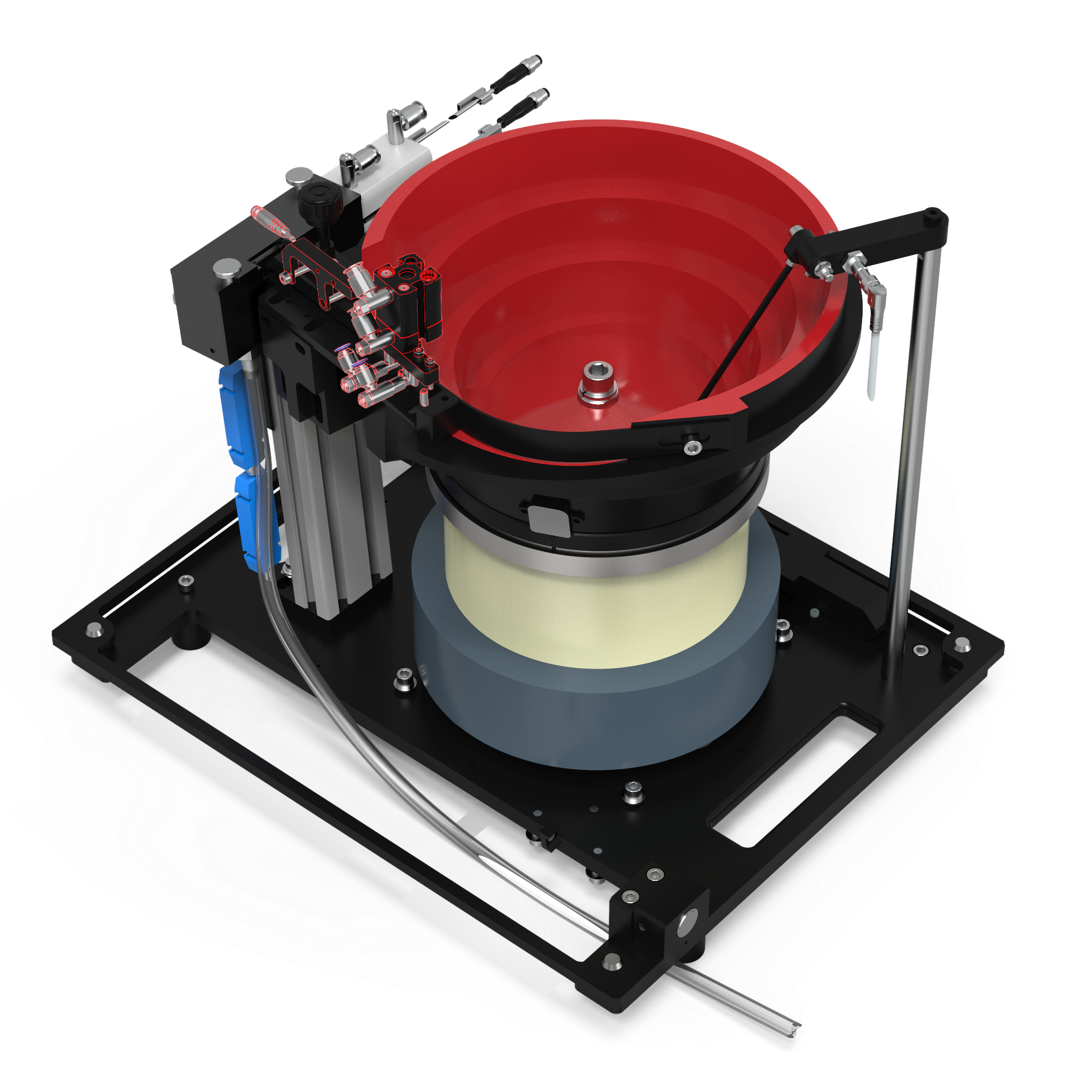

Step feeder or bowl feeder

Multiple types of loading heads

including auto-feeding, vacuum version for hard-to-reach points and pick & place

Optional pneumatic panel & logic control

to simplify integration

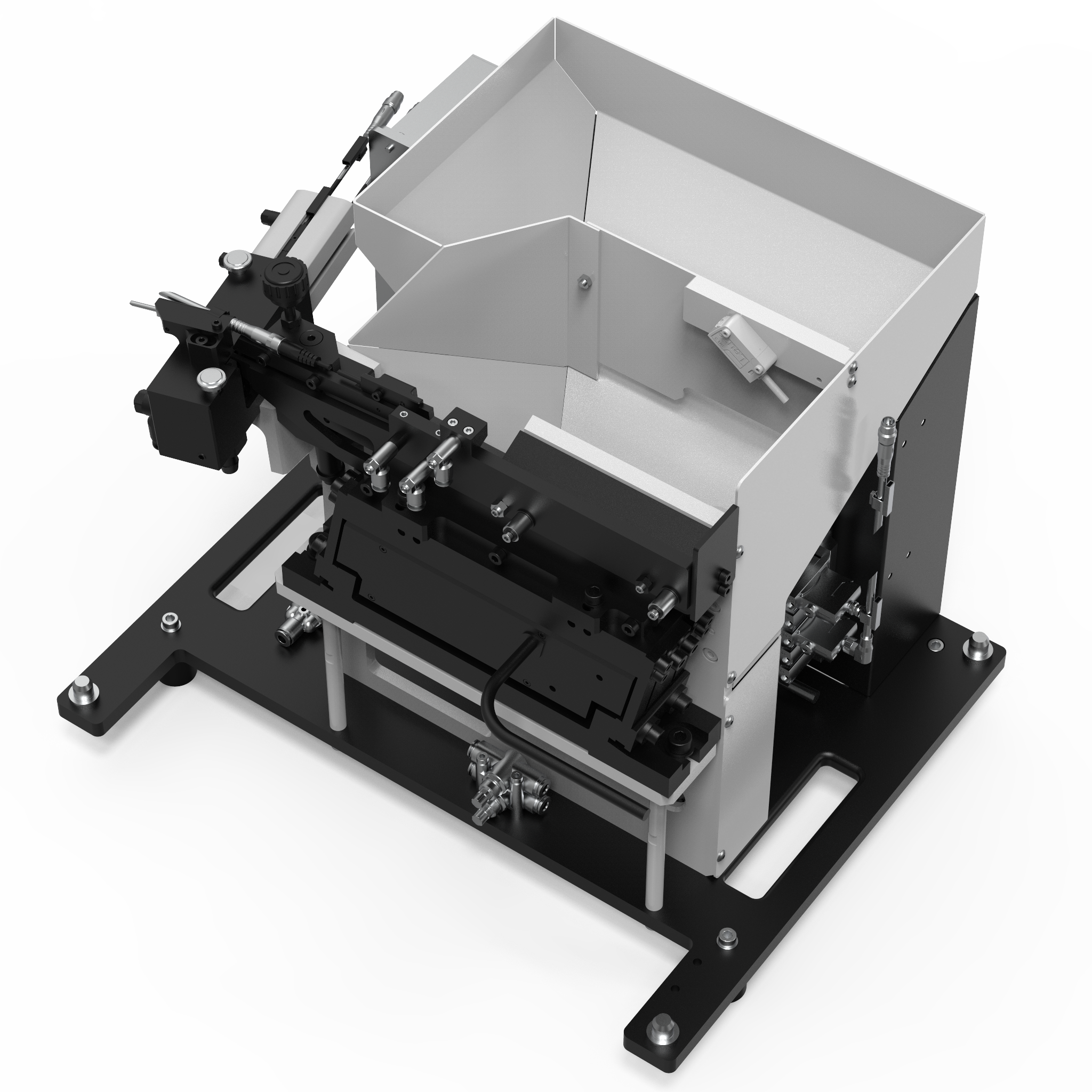

- Fill volume : 2.0L or 5.0L

- Reduced friction, particles and noise

- Fill volume: 0.4L, 1.0L or 3.0L

- Simple structure and easy maintenance

2 types of stations for 4 types of tightening modules

Screws are blown through the feed hose to the loading head.

RAPID's key benefits

Reliability and precision in every screw

Modularity

Vacuum types for hard to reach points

Vertical down, horizontal or bottom up direction

Auto-feeding or pick & place types to fit your needs

Optional Z-axis head stroke

Flexibility

Screw distribution, Screw mixing

Combined auto-feeding and pick & place

Additional fill volume

Optional screw particle cleaner, Optional logic control by RAPID

Quality & Reliability

Error-proof design

Validated solution before shipment

Quick reset from potential screw jam without tools

Maintenance friendly

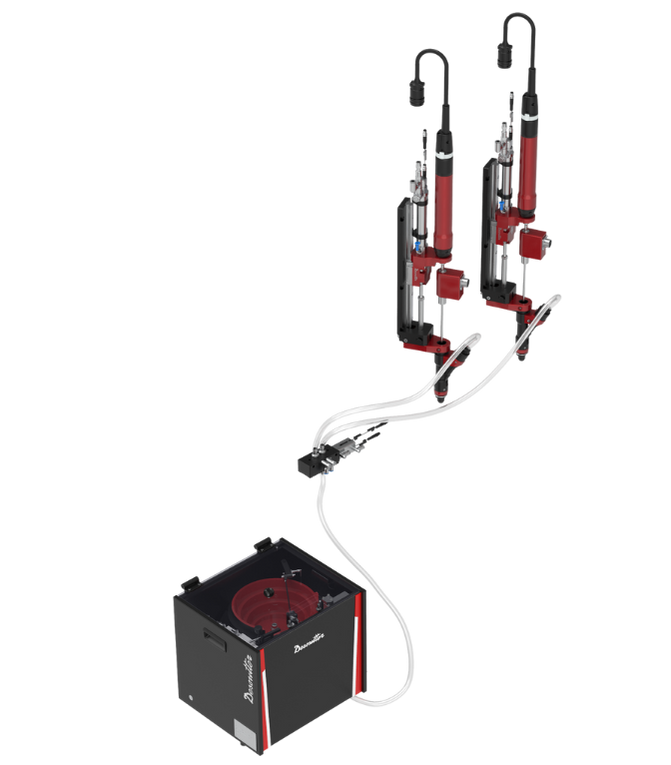

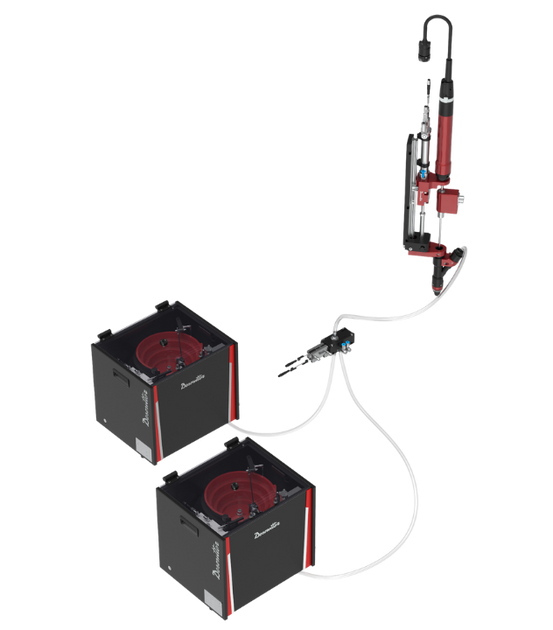

1 feeder for 1 or multiple tightening modules.

Compatibility to mix multiple screw types.

Particle cleaner to remove dust and oil.

Let's talk

Need a custom solution? Our team is here to help

They trust the RAPID

In their own words

The partnership between Desoutter and Autoliv is fruitful, stemming from effective collaboration. Together, we are working on innovative projects, enhancing efficiency and quality for our customers.

S. Perrault

Compatible screwdrivers

Compatible terminals

Your questions about RAPID answered

What types of screw feeding modules are available?

Screw feeding modules are essential components of automated assembly systems, ensuring fast and reliable delivery of fasteners (screws, nuts, studs…) to the tightening point. Desoutter highlights two common types, depending on the screw type, accessibility within the product, and the desired workstation configuration

Auto-Feeding / Blow Feeding (Pneumatic Feeding) modules: Screws are loaded into a vibratory bowl or step feeder. Compressed air then transports the screws one by one through a feeding hose directly to the loading head in the module. The module positions the screw above the tightening point on the product, and the tightening is performed by the electric screwdriver. This system enables extremely short cycle times, offering a highly cost-effective solution in terms of cost-to-takt time ratio.

Pick & Place modules: Depending on the shape of the screw and/or the need for compactness and lightness of the tool, this range is suitable for most situations. The module can be mounted on a robot or used manually. Screws are loaded into a vibratory bowl or step feeder. The module moves to pick up the screw from the feeder or external presenter, then positions itself for screwing, which is performed by the electric screwdriver. Its very simple integration and ability to reach difficult screwing points in highly compact stations make it a solution well worth considering.

Note: All types of Desoutter feeding systems are available for both automated stations and hand-held applications.

What feeders and accessories are available?

There are two feeder types:

Step feeder: Available in 2L or 5L capacities, it offers low friction and reduced noise, making it ideal for fasteners with delicate or sensitive coatings.

Bowl feeder: Offered in 0.4L, 1L, or 3L capacities, this feeder is known for its simple design and ease of maintenance.

And many additional accessories:

Hopper: Designed to increase fastener storage capacity and minimize refill frequency, hoppers are available in sizes ranging from 5L to 200L. The integrated belt system significantly reduces noise levels while gently feeding fasteners into the main feeder.

Distributor: It acts as a switching interface for managing multiple modules and/or feeders

Presenter: It allows the picking point to be positioned as close as possible to the screwing point when using a pick-and-place module. This significantly reduces the cycle time.

Particle cleaner: Positioned just after the feeder, it significantly reduces impurities on the screw and helps prevent contamination of the customer's product.

Shaft length check: Particularly well-suited for stations using similar screws, it serves as a poka-yoke mechanism to ensure the correct screw is used.

Manual receiving box: This accessory effectively replaces traditional screw boxes at the edge of manual workstations. It helps prevent operator slips caused by fallen screws on the floor, while also enabling screw counting to ensure proper assembly and product quality.

Break unit: This component primarily stores a screw before it reaches the module, helping to reduce cycle times caused by screw blowing. It can also function as a buffer before any accessory. Its receiving geometry is designed to preserve the integrity of screws with sensitive coatings

Can the system handle different screw types?

Yes, the system is capable of dispensing and tightening screws, nuts, and studs. The RAPID system also supports the mixing and distribution of fasteners across multiple tightening modules, making it ideal for complex assembly lines. A single feeder can supply multiple tightening modules, and each module can also be fed by multiple feeders—enabling the delivery of different fasteners to a single module.

How does the system ensure quality and reliability?

Preventive Design

Anti-jamming: The optimized geometry of the feeder, controlled rail filling, and air-pulse ejection of misaligned screws help reduce jamming risks to fewer than 5 per 100,000 screws.

Particle Management: An optional cleaning mode effectively removes metallic and greasy debris before screws enter the feed tubes.

Minimal downtime

Quick restart: Despite the high level of attention given to preventing jams, some may still occur. In such cases, the design of the feeders and tightening modules allows for quick, tool-free clearing, enabling the station to be restarted rapidly.

Easy and fast Maintenance: The system requires minimal maintenance to remain fully operational. Wear parts are easily accessible and, in most cases, can be replaced without the need for tools.

Real-Time Monitoring

Presence Detection: Laser or optical sensors verify the presence of screws before the tightening operation.

Torque Verification: Seamless integration with Desoutter screwdrivers enables full torque and angle data capture, ensuring complete traceability.

Rigorous Validation

5,000-Cycle Testing: Each system undergoes a real-world production simulation, including a comprehensive deep cycle testing process.

Is the RAPID system CE certified?

Yes, all RAPID screw feeding systems are CE certified, ensuring compliance with European safety and quality standards.

How can I get a customized solution for my application?

Desoutter has a dedicated team of experts ready to provide you with a customized configuration. You can contact us to discuss the specific requirements of your project.

Which robotic automation systems are compatible with RAPID?

RAPID can be easily integrated with a wide range of robotic systems, including industrial robots, collaborative robots (cobots), SCARA robots, and even XY-axis motion devices.

Is there an electric version of the RAPID screw feeding system?

Yes, it's called the eRAPID. It is the electric evolution of our RAPID screw feeding system, designed to deliver enhanced precision, control, and integration capabilities for modern assembly lines.

Go electric with eRAPID

the faster, smarter, cleaner evolution of RAPID.